The Rising Importance of China Titanium Fasteners in Global Industry

Titanium fasteners have revolutionized various industries by providing strength, lightweight properties, and corrosion resistance. As more companies look towards sustainable and efficient materials, the spotlight has increasingly focused on China titanium fasteners. This article delves into the importance of these fasteners, their manufacturing processes, and the myriad applications they serve.

Understanding Titanium Fasteners

Titanium fasteners are components made from titanium or its alloys, designed to connect and support different parts of machinery and structures. At the molecular level, titanium is known for its high strength-to-weight ratio and exceptional resistance to corrosion, which makes it ideal for various applications.

Why Choose China for Titanium Fasteners?

China has established itself as a leader in the production of titanium fasteners. Here are several reasons why China titanium fasteners have become a go-to choice for global companies:

- Cost-Effective Production: China benefits from advanced manufacturing techniques and lower labor costs, which make it possible to produce high-quality titanium fasteners at competitive prices.

- High-Quality Standards: Many Chinese manufacturers adhere to international quality standards, ensuring that the fasteners produced meet or exceed customer expectations.

- Diverse Range of Products: The multitude of manufacturers allows for a wide variety of titanium fasteners, including bolts, nuts, screws, and washers, to meet specific demands.

- Rapid Lead Times: With an efficient supply chain and production capacity, companies can expect shorter lead times when sourcing from China.

Types of China Titanium Fasteners

In the realm of titanium fasteners, there are various types, each serving its unique purpose. Below is a list of the most common types of China titanium fasteners:

1. Titanium Bolts

Titanium bolts are essential in connecting different machine parts. They are widely used in aerospace and automotive industries due to their high strength and lightweight characteristics.

2. Titanium Nuts

Titanium nuts work in conjunction with bolts to secure components together. Their resistance to heat and corrosion makes them ideal for high-stress environments.

3. Titanium Screws

Titanium screws are used in applications ranging from medical devices to construction. Their durable nature ensures longevity even in harsh conditions.

4. Titanium Washers

Titanium washers provide a smooth bearing surface, enhance load distribution, and prevent galvanic corrosion when used with dissimilar metals.

Application Areas of China Titanium Fasteners

The versatility of titanium fasteners allows them to be employed across a plethora of industries:

Aerospace Industry

In aerospace applications, weight savings are critical. The use of titanium fasteners allows for strong and lightweight assemblies that contribute to fuel efficiency.

Automotive Sector

The automotive industry increasingly adopts titanium fasteners to reduce overall vehicle weight without sacrificing performance or safety.

Marine Applications

Due to their exceptional resistance to corrosion, titanium fasteners are ideally suited for use in the marine environment, significantly prolonging service life.

Medical Equipment

Titanium fasteners are biocompatible, making them ideal for medical implants and devices that require reliable and safe fastening solutions.

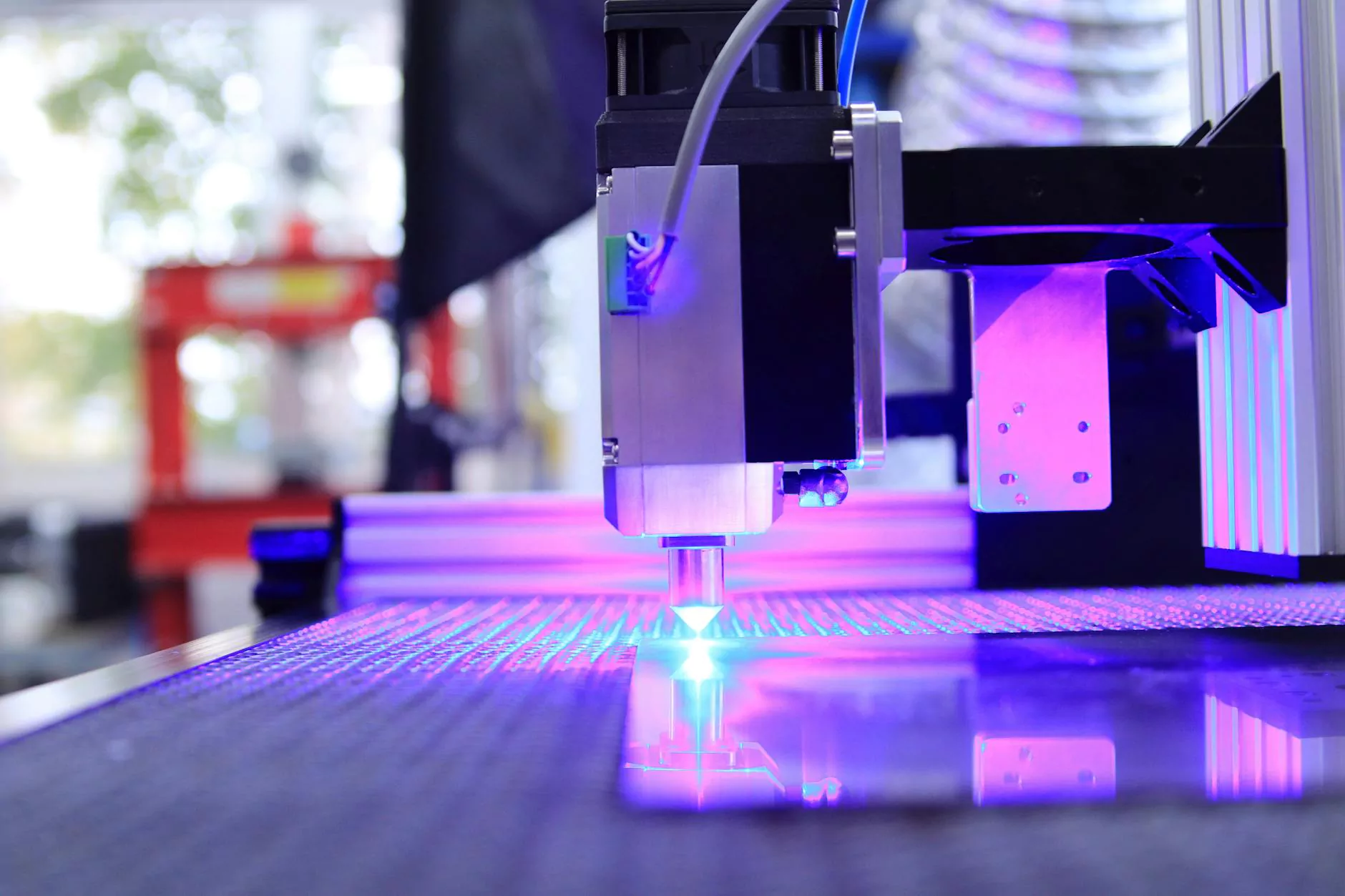

The Manufacturing Process of China Titanium Fasteners

The global dominance of China in manufacturing titanium fasteners is attributed to its efficient production methods. Here’s an overview of the typical manufacturing process:

1. Material Selection

The initial step involves selecting high-grade titanium raw materials which ensure better durability and performance.

2. Forging and Machining

The titanium ingots are forged into the desired shape through high-pressure techniques. Following forging, machining processes shape the fasteners to precise specifications.

3. Surface Treatment

Surface treatments like anodizing or passivation are applied to enhance corrosion resistance and durability.

4. Quality Control

Stringent quality control measures are essential. Each batch of China titanium fasteners undergoes rigorous testing to ensure compliance with international standards.

Benefits of Using China Titanium Fasteners

Choosing China titanium fasteners offers numerous benefits for businesses aiming for efficiency and durability:

- Enhanced Durability: Designed to withstand harsh environmental conditions, titanium fasteners display remarkable strength and plasticity.

- Weight Savings: Titanium is significantly lighter than steel, offering an excellent balance of strength and weight.

- Corrosion Resistance: Titanium naturally forms a protective oxide layer that resists corrosion, particularly in marine and chemical environments.

- Longevity: The durability of titanium fasteners results in longer service life and reduced frequency of replacements, enhancing overall cost-effectiveness.

Challenges and Considerations

While the advantages of China titanium fasteners are significant, there are challenges to consider:

1. Initial Cost

The initial investment for titanium fasteners can be higher than traditional options. However, their long-term benefits often outweigh these initial costs.

2. Machining Challenges

Machining titanium requires specialized tools and expertise due to its unique properties. Proper techniques must be adopted to avoid material damage.

3. Availability of Supply

While demand is high, ensuring a reliable supply chain is critical. Businesses should partner with reputable manufacturers to secure consistent quality and quantity.

Conclusion

In conclusion, China titanium fasteners represent a significant advancement in manufacturing robust, lightweight, and corrosion-resistant connections across various industries. From aerospace to medical applications, these fasteners offer unparalleled benefits that enhance operational efficiency and longevity. When considering the best fastening solutions, China’s reputable manufacturers provide quality assurance and innovative designs, ensuring customers receive products that meet rigorous standards. As industries continue to evolve, the demand for titanium fasteners in global markets will undoubtedly grow, solidifying their essential role in various applications.